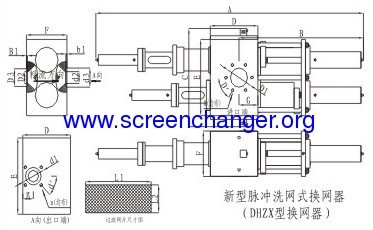

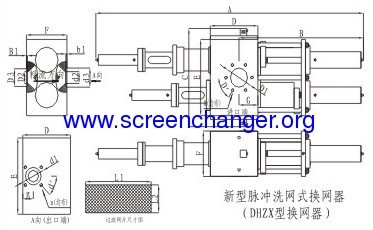

Continuous screen changer-pulse backflush screen changer

CONTINUOUS SCREEN CHANGER WITH BACKFLUSH SYSTEM

AUTOMATIC SCREEN CLEANING FOR MAXIMUM SCREEN SERVICE LIFE

High savings on screen costs, extremely short cleaning cycles at low melt loss and flushing the durable screens over the entire surface area are arguments clearly in favour of DEAO's fully automatic backflush system. The patented backflush system uses the short, clearance-free flow channels of the melt during filtering and also during the backflushing. Your benefit: Intelligent concepts reduce pressure and melt losses to a minimum, and increase screen service life and production reliability.

Advantages

• Processing capability for all thermoplastic materials

• Maximum screen service life - high savings on screen costs

• Optimal backflush effect - best possible flushing of screen over entire surface area

• Low wear and tear to the screen support piston by backflush add-on

• Highest production reliability - minimal staff costs - low need for maintenance

• More than 80% effective, free filter surface area

• Fully automatic operation - minimal melt loss

• Low investment costs, rapid amortization

.sheet

.coating

.pipe

.compounding

.wire and cable

.tubing

.lab lines

.textiles (fiber and nonwovens)

.EVA. hot melt adhesive and PSA

.Pelletizing(strands and under water)

.Recycling of most polymers

.Blown film and cast film

.FPVC. Corrosive and degradable materials

Technical data

Type | Screen size L×W (cm) | Screen area(cm2) | Pressure (Mpa) | Heating Power(kw) | Output(kg/h) |

DHZX-120 | | 193×2 | ≤25 | 14 | ≤2000 |

DHZX-160 | | 423×2 | ≤25 | 14 | ≤2500 |

DHZX-1800 | 47×19 | 900×2 | ≤25 | 14 | ≤3000 |

DHZX-2000 | 47×21 | 1000×2 | ≤25 | 14 | ≤4000 |

DHZX-2250 | 53×21 | 1125×2 | ≤25 | 14 | ≤4500 |

DHZX-2700 | 53×25 | 1335×2 | ≤25 | 14 | ≤5400 |

DHZX-3300 | 66×25 | 1650×2 | ≤20 | 20 | ≤6600 |

DHZX-4400 | 88×25 | 2200×2 | ≤20 | 20 | ≤8400 |

DHZX-5650 | 94×30 | 2827×2 | ≤20 | 20 | ≤11300 |