|

Deao Science & Technology Co., Ltd.

|

| Price: | 1.0~7000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Why do we need to use the screen changer for plastic extruder

When extruding plastics, a contamination-free plastic melt is desired. Since contamination affects the quality of the product and impedes the operating process, it is essential to ensure a perfect filtration process and improve the quality of the plastic melt by using a melt filter. A perfect filtration performance without any deterioration of the melt quality is possible with the well-proven DEAO Screen Changers, a large variety of which is incorporated into plastic extrusion machines.

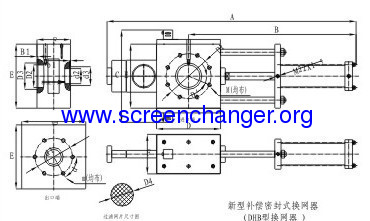

Hydraulic screen changer-non stop plate screen changer

non-stop plate screen changer, single plate screen changer, hydraulic screen changer with single plate type

Specification

1)Deao patented technology on the sealing system design. Automatic compensation on sealing gap can be realized during screen changing process.

2)Compatible with extruders for various polymers processing at high output.

3)Filtration screen diameter ranges from 70-360mm.

4)With highly precise design, the screen has good abrasive resistant, high pressure performance, ensuring large effective filtration area and improving filtration effect. It works well even under high temperature up to 300 ℃ and high pressure up to 50 MPa.

5)Screen changing time ≤ 2 seconds with pressure accumulator.

Technical Data

Type | Screen Diameter(mm) | Heating power(Kw) | Suitable Materials (Mpa) | Output(Kg/h) |

DHB-70 | Φ70 | 4.4 | ≤50 | 60-250 |

DHB-100 | Φ100 | 6.8 | ≤50 | 110-400 |

DHB-120 | Φ120 | 8.6 | ≤50 | 140-550 |

DHB-150 | Φ150 | 9.8 | ≤50 | 200-800 |

DHB-170 | Φ170 | 9.8 | ≤50 | 300-1000 |

DHB-200 | Φ200 | 11.6 | ≤50 | 400-1200 |

DHB-250 | Φ250 | 16.4 | ≤50 | 600-1800 |

DHB-300 | Φ300 | 16.4 | ≤50 | 800-2500 |

Benefits of hydraulic screen changer-non stop plate screen changer

-leak-free process

Minimum pressure drop

Improved products quality

Reduced waste materials

Reduced downtime & scrap

Reduced inlet pressure at extrusion die

Reduced temperature variations of the melt.

Applications

.PVC.PE.PP Wood-plastic profile extrusion line

.PVC wood door panel extruding production line

.Corrugated pipe production line

.co-extrusion single screw extruder

.granulation line

.PVC foamed plate production line

.PC.PMMA.PS.MS sheet production line

.PP.HIPS.PE.EVA.EVAOH single screw multi-layers composite sheet production line

PP.PE board production line

.PMMA transparent sheet production line

.PC.PP hollow profile board production line

.ABS single layer ,multi-layers composite sheet production line

.ABS.PP.PS anti-static co-extrusion sheet production line

.Wide floor sheet, water proof sheet production line

.PVC free foamed sheet, board, production line

.HDPE double wall corrugated pipe production line

.HDPE supplying water/gas pipe production line

.PP/PE recycling line,PVC hot-cutting pelletizing line

.two-stage recycling and granulation machine group

.PP-R pipe production line

.PET pelletizing line

.PP/PE waste film recycling and granulation production line

.Plastic plate material sheet material production equipment

.Double-wall Large Spiral Pipe Production Line

.Glass-fiber Reinforced Plastic Composite PP-R Extrusion Set

The hydraulic screen changer before deliver

v

v