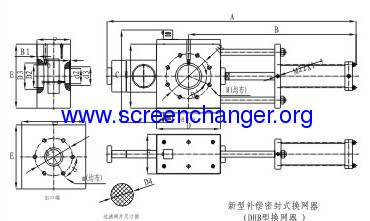

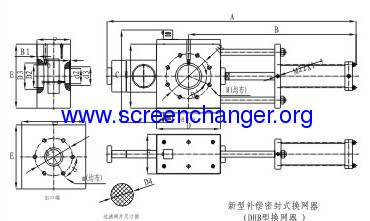

Screen changer for plastric polymer melt filtration

the screen changer consists of the main body of screen changer, slide plate and two breaker plates and electric controlling box, hydraulic station with accumulator.

Advantages

Advantages

patented technology on the sealing system design. Automatic compensation on sealing gap can be realized during screen changing process. Compatible with extruders for various polymers processing at high output.

Filtration screen diameter ranges from 70-360mm.

With highly precise design, the screen has good abrasive resistant, high pressure performance, ensuring large effective filtration area and improving filtration effect. It works well even under high temperature up to 300 ℃ and high pressure up to 50 MPa.

Screen changing time ≤ 2 seconds with pressure accumulator.

Benefits of DHB series of screen changer

leak-free process

Minimum pressure drop

Improved products quality

Reduced waste materials

Reduced downtime & scrap

Reduced inlet pressure at extrusion die

Reduced temperature variations of the melt.

Applications

Blown film and cast film (Bubble pack/ Medical/Food Wrap)

Sheet (Foam/Strapping/Plastic cardboard)

Coating (Hot melt adhesive)

Pipe ( Corrugated/Gas Pipe) and profile

Compounding (Master batch/filler)

Wire and cable extrusion

Tubing (Medical/Industrial/Irrigation)

Fibers ( Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers