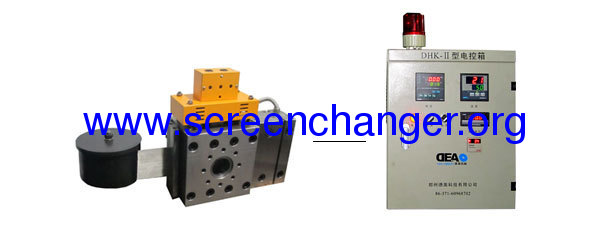

Automatic belt screen changer-plastic extrusions & melt filter

Automatic uninterrupted continuous polymer filtration

The automatic belt screen changer is a compact, self-contained screen changer that eliminates the need for hydraulics, screen packs, breaker plate cleaning or replacement, with no electric motors or hydraulics.

How to work skype:chinascreenchanger

How to work skype:chinascreenchanger

The screen moves across the flow of plastic melt and a fresh screen enters as the spent filter screen exits; removing the impurities from the raw material. The belt screen changer is fitted between the end flange of the extruder and the die. A cassette holding a roll of screen filter is attached to the side of the belt screen changer block. The controlling box of belt screen changer is equipped with a pressure sensor, and a pressure warning device, when the pressure is raise to the preset , it will automatically alarm, at the same time, the screen is replaced automatically. And the cooling system begin to work , the impurity is cooled and moved out with the filter screen.

Features include of the automatic belt screen changer-plastic extrusions& melt filter

1,performance characteristics:

automatical and continuous screen replacement without manual operation.

2,No fluctuation of material flow, no product deformation, excellent quality stability.

3,No waste product or waste material, and little material consumption occur when the

screen changer works.

Application fields:

Mainly used for the production of PP, PE,ABS, PS, PMMA and other materials, and widely used for the cast film, sheet, plate, optical fiber, various drawings, granulators and other products of high quality and long production process .