Automatic mesh belt screen changer

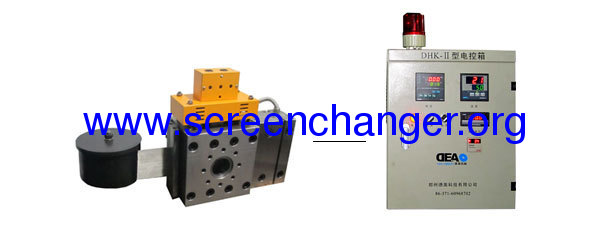

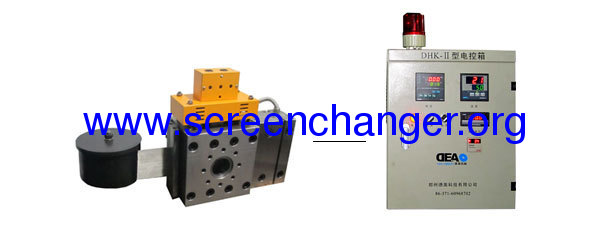

The automatic mesh belt screen changer is mainly composed of the screen changer, the heating and cooling system, and the electric control system. There is no need of manual operation of the screen changer because the material fluid inside flows by itself under the pressure caused by the melt production.

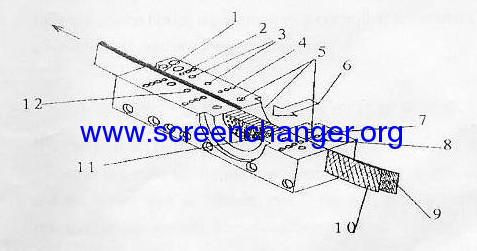

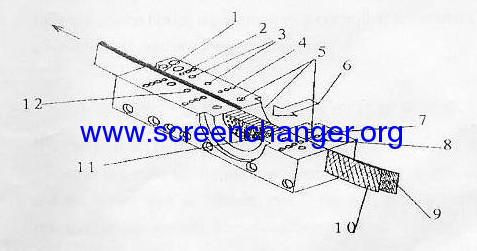

1)Moving screen mesh

heater;

2)Adiabatic isolation hole

3)Export cooling area water holes

4)Adiabatic isolation hole

5)Filtering district heating holes

6)Flow direction

11)Support of the porous plate mesh

12)outlet of cooling water holes

Performance characteristics:1\Automatical and continuous screen replacement without manual operation.

2\No fluctuation of material flow, no product deformation, excellent quality stability.

3\No waste product or waste material, and little material consumption occur when the

screen changer works.

Application fields:

Mainly used for the production of PP, PE, ABS, PS, PMMA and other materials, and widely used for the cast film, sheet, plate, optical fiber, various drawings, granulators and other products of high quality and long production process .

Technical Data:

Type | | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHW--70 | | 2.5 | ≤40 | ≤200 |

DHW--100 | 107×10 | 3.5 | ≤40 | ≤500 |

DHW--120 | 130×10 | 5 | ≤35 | ≤800 |

DHW--150 | 160×10 | 7.5 | ≤35 | ≤1500 |

DHW--170 | 180×10 | 12.5 | ≤35 | ≤2000 |

DHW--200 | 210×10 | 14 | ≤35 | ≤3500 |