|

Deao Science & Technology Co., Ltd.

|

| Price: | 1.0~7000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Continuous and automatic screen changer for polymer melt filtration

The automatic mesh belt screen changer is mainly composed of the screen changer, the heating and cooling system, and the electric control system. There is no need of manual operation of the screen changer because the material fluid inside flows by itself under the pressure caused by the melt production.

Technical Data:

Type | Screen Belt W(mm)×L(m) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHW--70 | 76×10 | 2.5 | ≤40 | ≤200 |

DHW--100 | 107×10 | 3.5 | ≤40 | ≤500 |

DHW--120 | 130×10 | 5 | ≤35 | ≤800 |

DHW--150 | 160×10 | 7.5 | ≤35 | ≤1500 |

DHW--170 | 180×10 | 12.5 | ≤35 | ≤2000 |

DHW--200 | 210×10 | 14 | ≤35 | ≤3500 |

Simply operation

The Continuou and automatic screen changer for polymer melt filtration is a compact, self-contained screen changer that eliminates the need for hydraulics, screen packs, breaker plate cleaning or replacement, with no electric motors or hydraulics. so it's easy for the operator , noe need to maintain the screen changer, what they need to do is replace the mesh belt when one roll screen expend.

How to work

1, the screen changer can be controlled by a pressure sensor.

2, the screen changer can be controlled by a time relay .

When screen change is requared

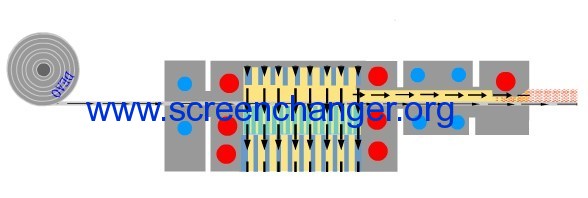

1, the cooling water pipe is opening all the time. it is ciculating on the screen entrance and exit of the mesh belt( you can see the blue color on above picture). And itcan make the polymer melt cool and get harden in the entrance and exit of the belt, and make a seal.

2, when the pressure is up to the preset, the heating pipe in the exit of the mesh belt begins to work, heats the harden polymer in the exit of the mesh belt( the red color at the right side you can see on the above picture). And another six heaters begin to heating to keep the temperature of the body of the screen changer.

3, the screen with impurities will move advance under a pressure difference or time relay controll. then the fresh screen enters into the working position .

4,the heating pipe shut down, and the polymer melt will get cool an harden again under the ciculating cooling water.

This process will repeat when screen change is required.

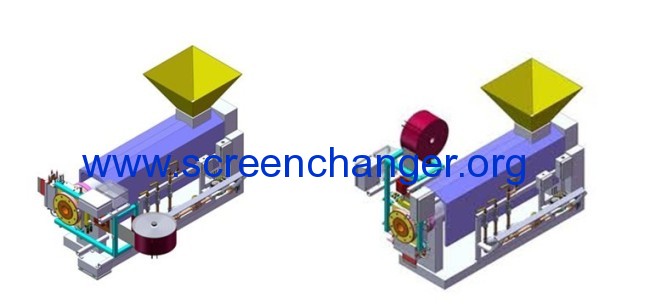

The Continuous and automatic screen changer for polymer melt filtration can be installed like this

The Continuous and automatic screen changer for polymer melt filtration is widely used for

1. Extruders (Plastic Extruder, Cast Film, Blown Film Extruder, etc)

2. Plastic pipe production line

3. Pipe, PA, PET and PVC sheet extrusion lines

4. Pelletizer,Granulation, Non-woven, Plastic recycling and Monofilament machine