The commissioning of the automatic mesh belt melt filter

When the body of the screen changer installed on the extrusion machine ,the water pipes (water inlet and out let) are connected with the faucet and turned on. , heaters connected to the temperature sensor(thermo couples), and when required the pressure sensor is fitted and connected to the pressure hole, we can start the machine at a slow speed.

When the polymer material enters the main body of the Screen Changer from the barrel cylinder, and passes across the flow channel and then exits the Screen Changer body. STOP THE MACHINE THIS TIME

Remark: this time is very important

1, observe whether have the polymer melt leak from the joint of the screen changer flanges and the barrel, if there is material leak from the joint, we should tighten the M24 bolt with the torque 230NM( not very precise, tighten the bolt until there is no material leakage)

2, when the polymer melt passed across the flow channel and exits the body of the screen changer, the polymer melts will leak from the screen entrance and screen exit. This is normal phenomenon. We just need stop the machine, Cooling water is circulating in the entrance and exit blocks and will soon make the polymer melt cool and harden. These hardened polymer material create a seal at both the screen Entrance and exit – keeping the polymer in and air out, and prevent the polymer melt material leak .

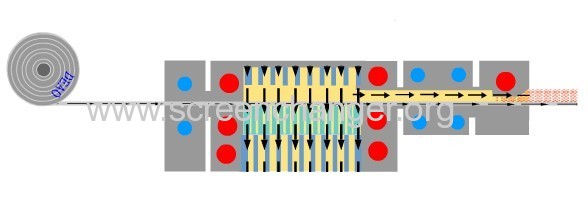

When the extruder is running, the

automatic screen changer unique design uses an integrated process relying on cooling and heating of the melt and pressure to control the change of the screen.

TIME FOR A SCREEN CHANGE

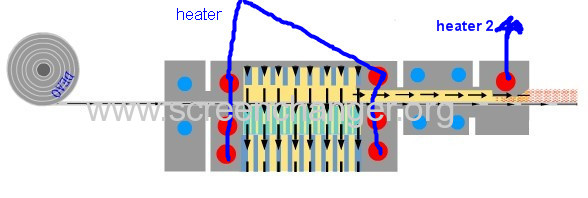

Red color: heating system

Blue color: cooling system

When screen change

1), Cooling – the cooling water is circulating all the time, you can see from the picture above, the cooling water pipes are in the positions that the screen entrance and screen exit. This creates a seal at both the screen Entrance and exit– keeping the polymer in and air out . At the Screen Exit the water-cooling maintains a solid Polymer Plug (seal) that contains the filter screen.

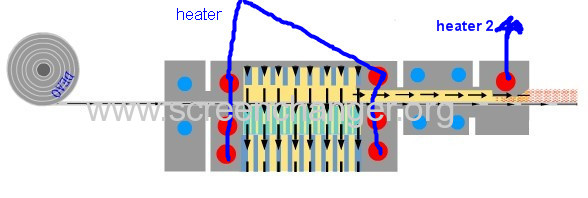

2). Heating – When the screen change is required, the warning device alarming , the heaters at the screen exit (heater 2)begins to work, heats the hardened polymer at the screen exit. and make them to melt . Six high quality heaters maintain temperature levels in the main body of the

automatic belt screen changer

3). Screen move forwards- The dirty screen (containing the screen and impurities) begins to moves forward about 2-4cm , and the fresh screen move into the body of the

screen changer.

4)Polymer melt cool and harden to seal the screen exit– the screen exit heater (heater 2) is shut-off and the soften Polymer Plug again hardens, sealing the exit. Ready for the next screen change…1,2,3,4.