DHW series automatic belt screen changer

Auto belt screen changer for extrusion lines

Automatic uninterrupted continuous polymer filtration

The automatic belt screen changer is a compact, self-contained screen changer that eliminates the need for hydraulics, screen packs, breaker plate cleaning or replacement, with no electric motors or hydraulics.

How to work

The screen moves across the flow of

plastic melt and a fresh screen enters as the spent filter screen exits; removing the impurities from the raw material. The belt screen changer is fitted between the end flange of the

extruder and the die. A cassette holding a roll of screen filter is attached to the side of the belt screen changer block. The controlling box of belt screen changer is equipped with a pressure sensor, and a pressure warning device, when the pressure is raise to the preset , it will automatically alarm, at the same time, the screen is replaced automatically. And the cooling system begin to work , the impurity is cooled and moved out with the filter screen.

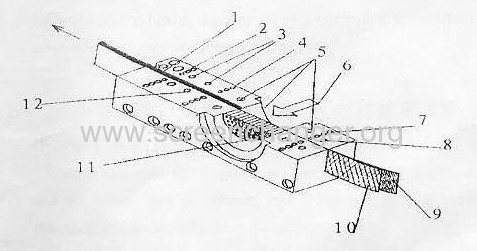

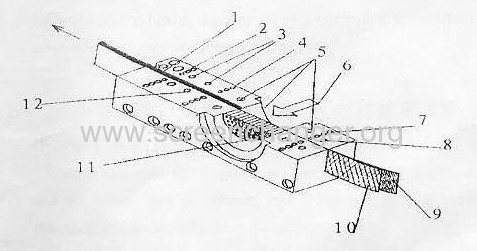

(1)Moving screen mesh heater;

(2)Adiabatic isolation hole

(3)Export cooling area water holes

(4)Adiabatic isolation hole

(5)Filtering district heating holes

(6)Flow direction

(7)inlet heat insulation hole

(8)outlet cooling water area

(9)Fine mesh belt

(10)Support mesh(coarse screen)

(11)Support of the porous plate mesh

(12)outlet of cooling water holes

Widely used for:

1. Extruders (Plastic Extruder, Cast

Film, Blown Film Extruder, etc)

2. Plastic

pipe production line

3. Pipe, PA, PET and

PVC sheet extrusion lines

4.

Pelletizer,Granulation, Non-woven, Plastic recycling and Monofilament machine

Type | Screen Belt W(mm)×L(m) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHW--70 | 76×10 | 2.5 | ≤40 | ≤200 |

DHW--100 | 107×10 | 3.5 | ≤40 | ≤500 |

DHW--120 | 130×10 | 5 | ≤35 | ≤800 |

DHW--150 | 160×10 | 7.5 | ≤35 | ≤1500 |

DHW--170 | 180×10 | 12.5 | ≤35 | ≤2000 |

DHW--200 | 210×10 | 14 | ≤35 | ≤3500 |