Automatic belt polymer melt filter

Automatic mesh belt screen changer/Melt filter

Why choose us?

Our screen changer advantages:

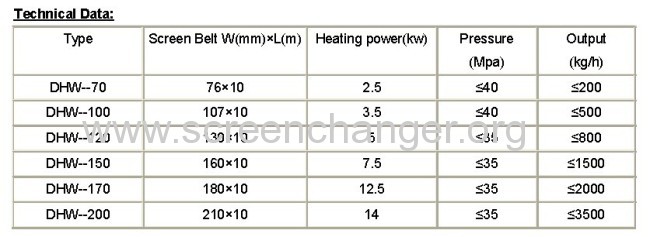

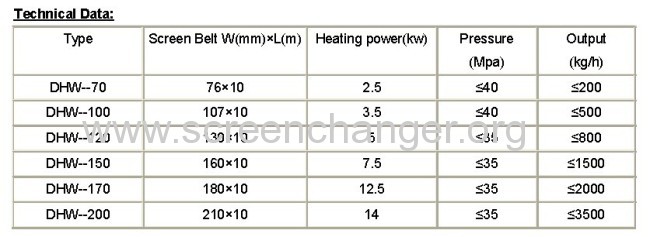

1. Large capacity, large filtering area: Capacity can be reached 20-3000 kg/h, Filtering area: 30-1256cm2.

2. Continuous process:no material leakage, no need to stop the machine when changing the screen, no production disruption or interference

3. High pressure and temperature resistant: max operation pressure can be 350 bar, temperature : 330°C.

4. Automatic without manual work: fully automatic belt filter without manual work;

5. Good wear-resistance: high-quality, high-performance alloy material after precise finishing and particular hardening.

6. Easy maintenance: easy to install and maintain, reliable and economical.

7. Wide range of choices: we provide different dimensions of product which can meet various needs.

Automatic belt polymer melt filter is mainly composed of the screen changer, the heating and cooling system, and the electric control system. There is no need of manual operation of the screen changer because the material fluid inside flows by itself under the pressure caused by the melt production.

Automatic belt polymer melt filter performance characteristics

Automatic belt polymer melt filter performance characteristics1. Automatically and continuous screen replacement without manual operation.

2. No fluctuation of material flow, no product deformation, excellent quality stability.

3. No waste product or waste material, and little material consumption occur when screen changer works.

4. Simple construction, reliable operation; Easy maintenance, lower running cost.

Applications

1. Extruders (Plastic Extruder, Cast Film, Blown Film Extruder, etc)

2. Plastic pipe production line

3. Pipe, PA, PET sheet extrusion lines

4. Pelletizer,Granulation, Non-woven, Plastic recycling and Monofilament machine

The whole set of Automatic belt polymer melt filter

The whole set of Automatic belt polymer melt filter before delivery

The screen changer can be installed horizontally and slantly and vertically

The screen changer can be installed horizontally and slantly and vertically