•It has no motor or moving mechanical parts. It requires minimum maintenance interventions, continuous production achievable evening during belt screen replacement.

1. Extruders (Plastic Extruder, Cast Film, Blown Film Extruder, etc)

2. Plastic pipe production line

3. Pipe, PA, PET and PVC sheet extrusion lines

4. Pelletizer,Granulation, Non-woven, Plastic recycling and Monofilament machine

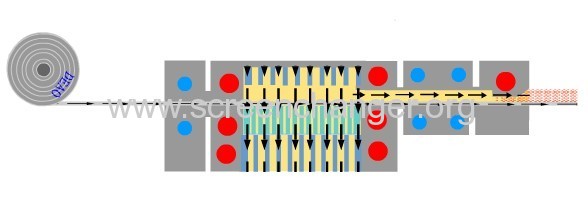

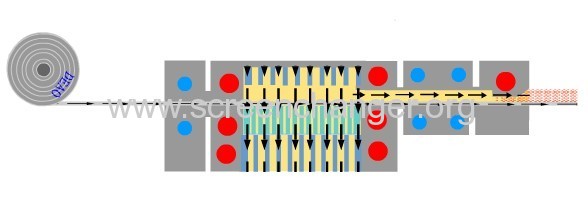

How to work

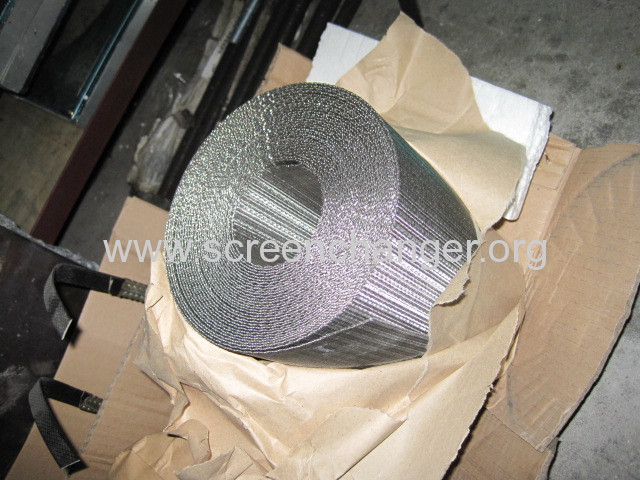

The screen moves across the flow of plastic melt and a fresh screen enters as the spent filter screen exits; removing the impurities from the raw material. The belt screen changer is fitted between the end flange of the extruder and the die. A cassette holding a roll of screen filter is attached to the side of the belt screen changer block. The controlling box of belt screen changer is equipped with a pressure sensor, and a pressure warning device, when the pressure is raise to the preset , it will automatically alarm, at the same time, the screen is replaced automatically. And the cooling system begin to work , the impurity is cooled and moved out with the filter screen.

Red color: heating system

Blue color:cooling system

When screen change

1), Cooling – water (8 –20 degrees C) is circulating in the entrance and exit blocks. This creates a pressure tight Polymer Plug or seal at both the screen Entry port – keeping the polymer in and air out and at the Exit port. At the Screen Exit the water-cooling maintains a sold Polymer Plug (seal) that contains the filter screen.

2). Heating – When a screen change is needed the two cartridge heaters at the exit, heats the tip of the Polymer Plug permitting it to move. Four high quality cartridge heaters maintain temperature levels in the main section of the auto continuous screen changer

3). Screen Advances - The Polymer Plug (containing the screen and impurities) that is under pressure moves out of the exit for a predetermined length determined by the timer or pressure regulator or manual operation. This also moves the contaminated screen across the flow of plastic and a fresh screen section enters.