Technical Data:

Type | Screen type (mm) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHBL-80 | 70×70 | 3 | ≤50 | ≤250 |

DHBL-100 | 100×90 | 5.6 | ≤50 | ≤450 |

DHBL-130 | 120×110 | 6.8 | ≤40 | ≤550 |

DHBL-150 | 140×130 | 8 | ≤40 | ≤900 |

DHBL-200 | 190×170 | 10 | ≤30 | ≤1500 |

continuous screen changer especial for foaming products

1, especial for XPS,EP,EPS foaming plate products and cast film

2,no need to stop the working machine

3, no material leakage or product...

Screen changer, continuous screen changer, hydraulic screen changer.

Features include

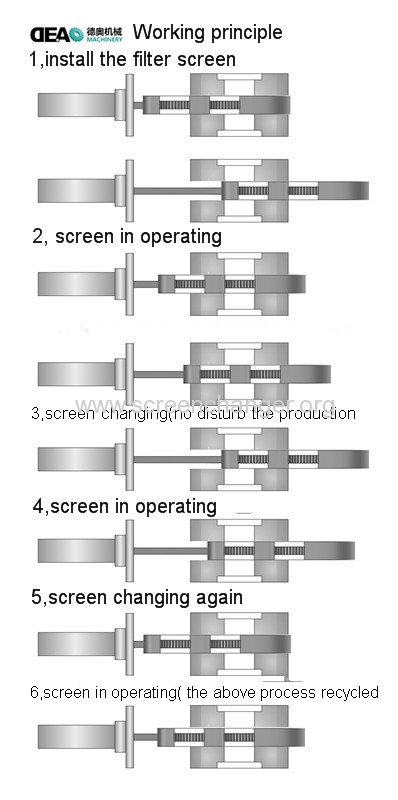

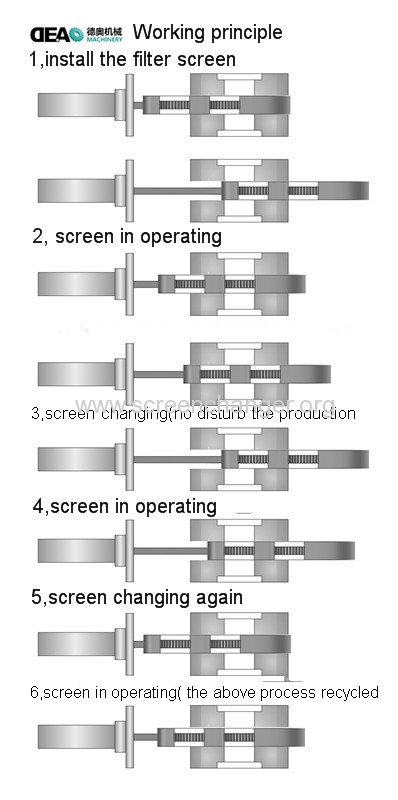

the new continuous screen changer is based on the single plate screen changer, and it add the auto exhaust system , and the two filter screen cavities distance is very close, when the screen replace is required, the plate with dirty screen is moved out and the new screen is moved to the working position. and the exhaust system started at the same time. so our screen changer can not only filter impurities, but also can greatly improve the plasticizing and homogenization effect of the raw material, make the product structure more homogeneous and product surface smoothness and higher quality .

Our advantages

We are specialized in the research and manufacturing of

melt filtration device /screen changer for more than 20 years. With strong scientific research team and mature technology; hold many international and national invention patents. There are five kinds of screen changer :

single plate screen changer , double pillar screen changer, new cntinuous screen changer, backflush screen changer. automatic belt screen changer.Our items can not only filter impurities, but also can greatly improve the plasticizing and homogenization effect of the raw material, make the product structure more homogeneous and product surface smoothness and quality much better, energy-saving and consumption-reducing, output- increasing and labor-saving