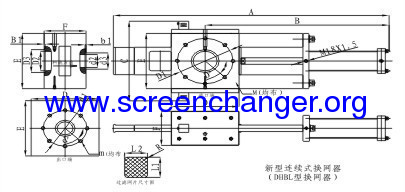

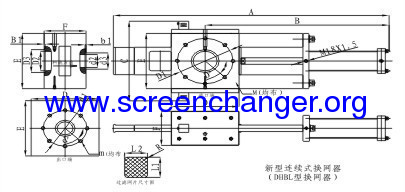

DHBL series continuous screen changer

This series of screen changer consists of main body, slide plate, heater, hydraulic unit, temperature control system and pressure monitoring system. Different from the above Single-plate type screen changer, it changes the screen without interrupting extrusion production.

Features of DHBL series continuous screen changer

With highly precise design, abrasive resistant, high pressure performance, ensuring larger effective filtration area and enhancing filtration effect.

Simple operation and easy cleaning process.

It works well even under high temperature up to 300 ℃ and high pressure up to 50 MPa.

Breaker plates can be taken out from slide plate for easy cleaning. They are especially applicable to foaming plate products such as XPS, EPS, EPE and cast film. It ensures the screen changing without machine halt or production interrupt, which has been widely tested and verified in production practice.

Application fields:

1,Applicable to all kinds of

plastic products.

2,Applicable to the

production line of chemical fiber, rubber, collosol, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture.

.Tubing

.Lab lines

.Coating

.Compounding

.wire and cable tubing lab lines

.EVA, hot melt adhesive and PSA

.Pelletizing ( strands and under water)

.Blown film and cast

film.Degradable materials

Technical Data:

Type | Screen type (mm) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHBL-80 | 70×70 | 3 | ≤50 | ≤250 |

DHBL-100 | 100×90 | 5.6 | ≤50 | ≤450 |

DHBL-130 | 120×110 | 6.8 | ≤40 | ≤550 |

DHBL-150 | 140×130 | 8 | ≤40 | ≤900 |

DHBL-200 | 190×170 | 10 | ≤30 | ≤1500 |