Plate type continuous screen changer

| Price: |

1.0~40000.0 USD |

| Payment Terms: |

T/T |

| Place of Origin: |

Henan, China (Mainland) |

Product Detail

Model No.:

DHBL

Production Capacity:

50 pieces per month

Delivery Date:

40 days after receiving dow...

Function:

filtration of the plastic m...

Auxiliary equipments for plastic extrusion plants:

for plastic extruder

material:

high quality alloy steel /3...

Means of Transport:

Ocean,Air

Packing:

seaworthy packing

Structure:

Hydraulic Filter

Brand Name:

DEAO

Application:

almost all polymers PP/PE//...

different type:

match with different type o...

Plate type continuous screen changer

non stop the on-going machine/

no disturb the production when change the screen

no material leakage

Plate type continuous screen changer

This kind of screen changer DHBL series is our new patent products.

we are the only one manufacture in the whole China.

This kind of plate type continuous screen changer makes up the deficiency (interrup the product when change the screen) of the tradtional plate type screen changer. Now is widely used for the XPS/EPE/EPS such foaming products extrusion lines, and plastic recycling granulator, and fiber ( such as PET wig hair extrusion line)

The advantages of this kind of plate type continuous screen changer

The advantages of this kind of plate type continuous screen changer

1, Eliminates extrusion line shutdown when change the screen , thus increasing the production capacity

2, without interrupting material flow and without interrupting the production when change the screen,

3, Leak-free mode of operation

4, Equipped with feed material system and air vent system , improve the quality of the products.

4, high operational reliability

5, Flow chanel geometry without any dead spots

6, Easier operation and less interfer of the operater

7, Quick delivery time , as soon as 10 days after makeing a purhase order.

The disadvantages of this kind of plate type continuous screen changer:

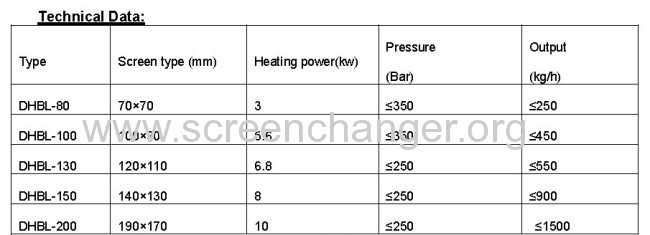

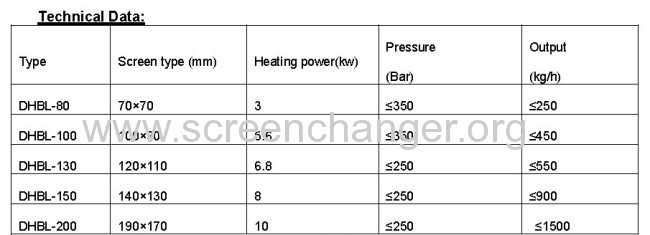

So far the biggest type is DHBL-200, and this type fit for the output less than 1500kg/h. If the output is higher than this, this kind of screen changer can not meet the demands. so this kind of screen changer can be applied for the production capacity lower than 1500kg/h. And for some high yield device we have special kind of screen changer. our back flush screen changer

Applications

1,Applicable to all kinds of plastic products.

2,Applicable to the production line of chemical fiber, rubber, collosol, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com