Continuous screen changer for XPS/EPE/EPS foaming products extrusion line

The new continuous screen changer is especially applicable to foaming plate products such as XPS, EPS, EPE and cast film. It ensures the screen changing without machine halt or production interrupt, which has been widely tested and verified in production practice.

Type | Screen type (mm) | Heating power(kw) | Pressure (Mpa) | Output (kg/h) |

DHBL-80 | 70×70 | 3 | ≤50 | ≤250 |

DHBL-100 | 100×90 | 5.6 | ≤50 | ≤450 |

DHBL-130 | 120×110 | 6.8 | ≤40 | ≤550 |

DHBL-150 | 140×130 | 8 | ≤40 | ≤900 |

DHBL-200 | 190×170 | 10 | ≤30 | ≤1500 |

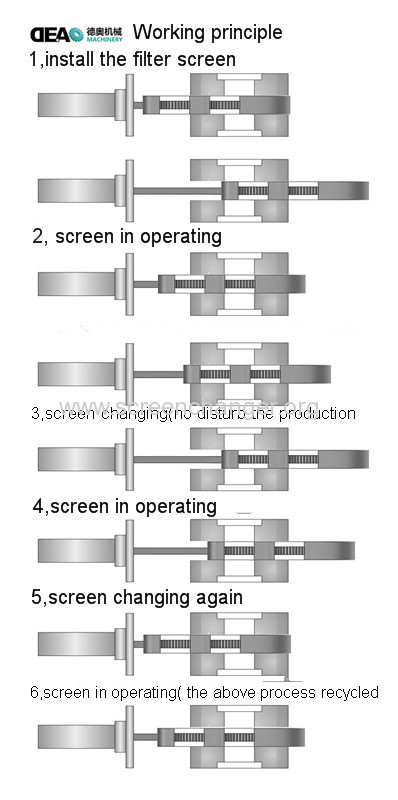

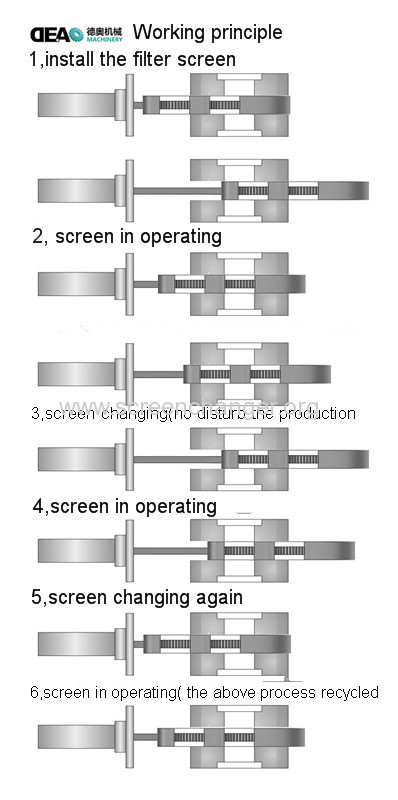

How to work

You can see clearly the continuous screen changer how to work , and the process of the screen changing time.

Last week this continuous screen changer installed on a hair wig extrusion line, and geta good effect, the wig hair is so gracile and easy to be interruped, but aplied our continuous screen changer, the hair wig mono filament is not be interrupted during the screen changing time. which made the customer satisfied, and they prepareed to buy for their other extrusion line. And also it's an encourage for us, provide the customer's satisfied products is our mission and responsiblity.

20 years is a long time, we are always move forward stablility. continuously technological innovation make us outstanding from our competitors. as the iniator of continuous

screen changer in China, we are always standing in the forefront.