The solution of the screen changer for granulator

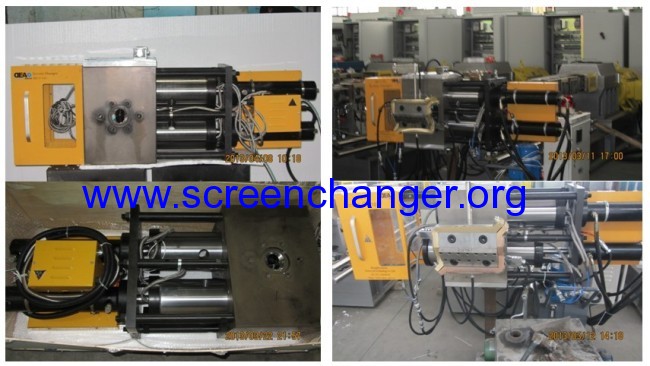

1, S

ingle plate double working position screen changer and hydraulic power unit with accumulator- which can realize non-stop the working machine when change the screen, and at the moment of screen changing, will have some interrupted bar, and the bar with larger diameter will not be interrupted . the advantage is : the price is cheap.

2,

Single plate double working position screen changer and hydraulic power unit and electrical controlling pack- this solution is based on the first one, but equipped with the electrical controlling pack, which include an pressure sensor and sound-light alarm device. It can be automatically alarming when need to change the screen, reminder to change the screen, exclude the effects of quality caused by the impurities excessively block the screen . Partitioning temperature control, make the screen changer heating temperature precise and stable.

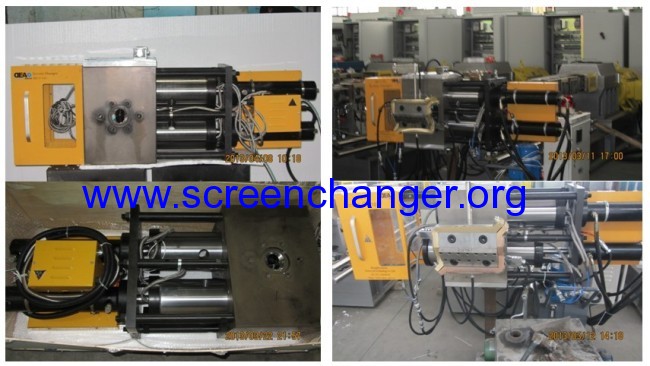

3,

Double piston double working position screen changer and hydraulic power unit and electrical controlling pack- which realize non-stop the machine when changing the screen, and the fluctuation of the melt pressure is small, designed with lead material and exhaust system, no disturb the production. Equipped with high-level melt pressure sensor and sound-light alarm device. Which can be alarm automatically when need to change the screen, exclude the effects of quality caused by the excessively blocked screen. This kind of screen changer can realize that automatically feed material and exhaust the air, accuracy controls the material feed biases precision, maximum reduce the effect of the quality caused by changing the screen.

4,

New continuous screen changer andhydraulic power unit-which can relize no interrupt of production when change the screen. Equipped with exhausted system, improve the qualityof the pellets ,no bubbles in the pellets.

5,

Automatic belt screen changer and electrical controlling pack- which can realize non-stop the working machine , and full automatically, no need manual operation, the melt pressure an material fluid no fluctuations, which realize the stability and continuous production. This kind of screen changer is fit for that require high continuously and pressure stability production.

6,

New pulse backflush screen changer and hydraulic power unit and PLC- which can realize the non-stop the working machine ,no interrupt the production. This kind of

screen changer equipped with self-cleaning system, no need to change the screen ,but backflush with a little clean material , the control program is preset in he PLC controlling pack.