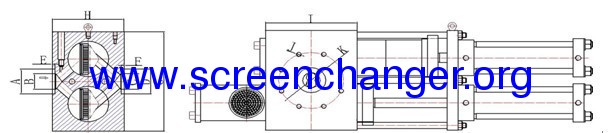

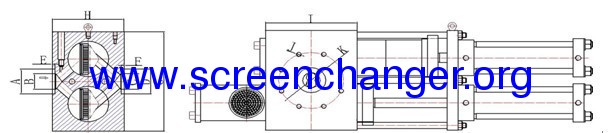

Double-piston continuous screen changer realizes a non-stopping screen changing operation by altering two pistons with double filtering areas. During production, the polymer melt is divided into two flow channels inside the screen changer housing, then conveyed through the two filters equipped with the appropriate filter medium. This filter medium consists of screen packs supported by breaker plates.

Features of plastic extrusion hydraulic continuous screen changer- double piston type

1, It can match with extruders of different design. It is applicable to process with most polymers at high output.

2, Double-channel nonstop

screen changer work alternatively, which can change the screen with minimum melt pressure fluctuating and production interrupting.

3, Two stages air vent for the hydraulic system to eliminate bubbling in polymer flow.

4, Superior sealing system completely eliminates polymer leakage.

5, External safety cover gives better appearance and safe protection.

1, Eliminates line shutdown thus increasing production

2, Leakage-free process

3, Two breaker plates design increases filtration area compared to single breaker plate design

4, Reduced downtime & scrap

5, Reduced inlet pressure at extrusion die

6, Reduced temperature variations in the melt ·

Applications

Blown film and cast film (Bubble pack\ Medical\Food Wrap)

Sheet (Foam\Strapping\Plastic cardboard)

Coating (Hot melt adhesive)

Pipe (Corrugated\Gas Pipe) and profile

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers

Technical Data

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | square screen | 900x2 | 14 | 2000--6000 |