Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | screen wrapped on the slide bar | 900x2 | 14 | 2000--6000 |

Applications

cast film (Bubble pack\ Medical\Food Wrap)

Sheet (Foam\Strapping\Plastic cardboard)

Coating (Hot melt adhesive)

Pipe (Corrugated\Gas Pipe) and profile

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers

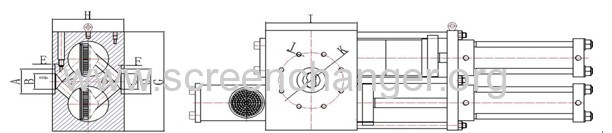

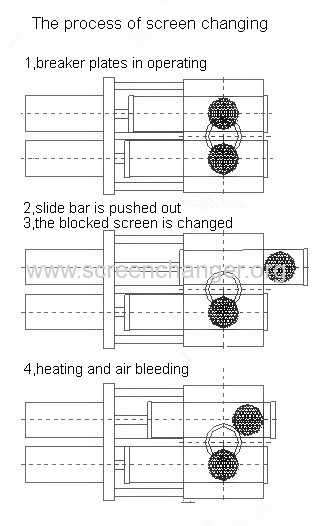

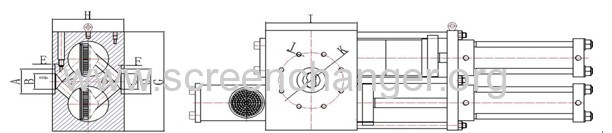

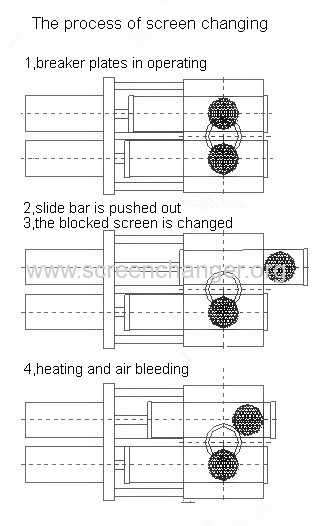

Picture shows the screen changer how to work

The screen changing process is controlled by the electrical controlling box.

Our main competitors:

1, Kreyeborg GmbH

2,Nordson Xaloy

3, JSW,the Japan steel works

4,PSI-polymer system

5,Gneuss melt filtration system

Compare with them, we have many unique advantages

1, over 20 years R&D experience in the polymer melt filtration .

2, high quality product with lower price

3, quick delivery time, as quickly as one week

4,full time service, 24 hours telephone online: +008613633833227

Some pictures of the double pillar screen changer for plastic melt filtration