the replacement without machine halt is ensured and no interrupt of material fluid and of production will occur.

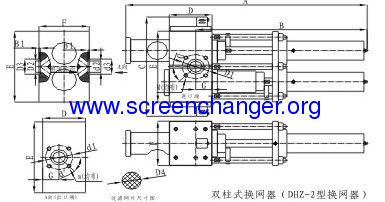

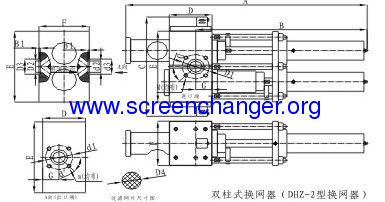

The double pillar screen changer

The dual-column double-position hydraulic screen changer is designed to work with two channels inside. It contains two screens that work at the same time: one screen works, while the other one is changed during the process of screen replacements, thus the replacement without machine halt is ensured and no interrupt of material fluid and of production will occur. Therefore, the

screen changer meets the customers' requirement of higher productivity and better quality.

Performance characteristics:1\Special sealed structure design(self-owned patent),excellent effect, no material leakage for more than five years.

2\Dual channels for filtration, no need to stop the working machine when changing the screen, no production interrupt, and more efficiency and less energy consumption without any defective product. Especially appropriate for the production of cast film, plate and sheet.

Application fields:

1\Used for the production of plate, sheet, cast film, pipe, granulation and so on.

2\Applicable to the production line of collosols, adhesive, coating and finishing materials and other blending agent products, used for filtration of the material mixture, filtering screen replacement available without machine halt.

Technical Data:

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | Φ300 | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | Φ900 | 900x2 | 14 | 2000--6000 |