Specification

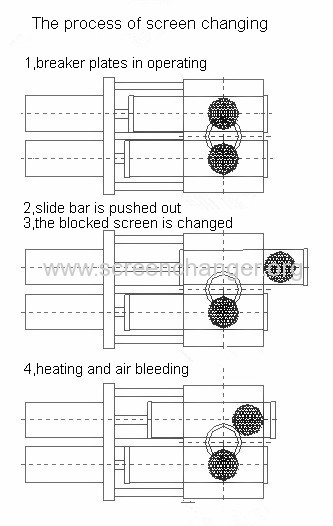

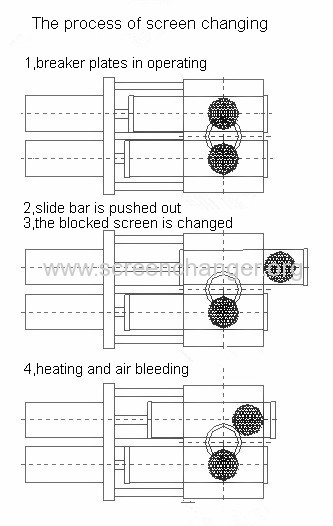

1,Automatic screen changing by hydraulic; Machine non-stopped

2,Special sealed structure design(self-owned patent),excellent effect, no material leakage for more than five years.

3, Simple construction, reliable operation; Easy maintenance, lower running cost;

Performance characteristics:

1,Dual channels for filtration, no need to stop the working machine when changing the screen, no production interrupt, and more efficiency and less energy consumption without any defective product. Especially appropriate for the production of cast film, plate and sheet.

2,The function of filling material exhaust and pollution discharge guarantee the process of replacing screen continuously. Exhaust system device can fully defuse the gas mixed in the materials and improve the product quality.

Application fields:

.sheet

.coating

.pipe

.compounding

.wire and cable

.tubing

.textiles(fibers and nonwovens)

.EVA, hot melt adhesive and PSA

.pelletizing(strands and underwater)

.recycling of most polymers

.blown film and cast film

.corrosive and degradable materials

.Textiles (fibers and nonwovens)

Technical Data

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | square screen | 900x2 | 14 | 2000--6000 |