Double channel screen changer

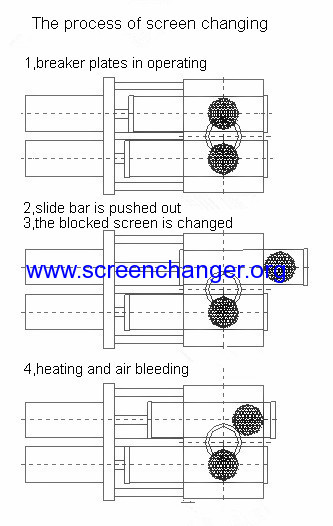

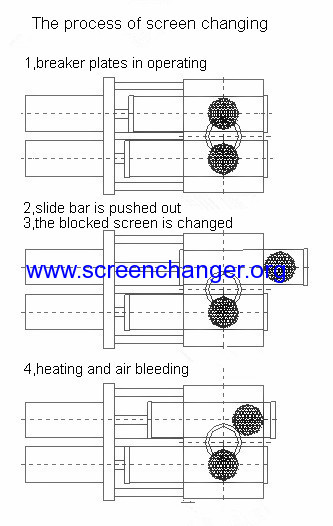

The double channel screen changer also called non-stop continuous screen changer, it is function is filtration the impurities of the plastic polymer melt according to the filter screen in the working position. When the impurities run up to some degree, we can change the filter screen directly and no need to stop the on-gong machine or reduce the speed of the machine, to enhance the productivity, and save energy and reduce consumption.

Benifits of this kind of screen changer

(1)no need to stop the working machine, or remove the flange to clean the impurities on the breaker plate, Reduce the labor intensity of workers, improves the production efficiency,and also reduced the incidence of waste;

(2) no need to cooling down and warming up, reduce the consumption of electric energy.

(3) non-stop the working machine, no need to remove the flange, improve the production efficiency, and enhance the workers' efficiency , make benefit to the enterprise

(4) the most important thing: filter the impurities out of the melt material, improve the quality of the product, showing directly on the appearance of bright and clean .

(5), reduce the abrasion to the die, extend the service life of the die

(6)the added

screen changer, make the runner longer, Improve the plasticizing and homogeneity of melt, at the same time improve the quality of products.

Technical Data

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | square screen | 900x2 | 14 | 2000--6000 |