Plastic extruder continuous screen changer

Features of this kind of plastic extruder screen changer

Features of this kind of plastic extruder screen changer

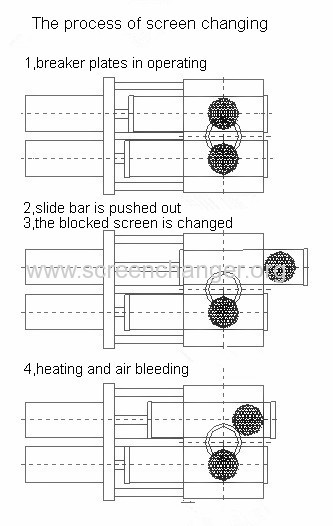

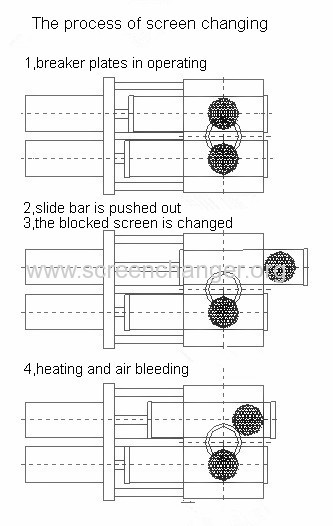

It is unnecessary to stop the working machine when applied this kind of screen changer, at the same time it can dispense much labor. As per the design, there are two pistons, and each piston holds a screen cavity, we put the screen on the breaker plate, and then put into the screen cavity. General time, the two screens are on the working position , when the pressure rise to the pressure set , the warning device alarming, it's the signal of screen change time.

At this time, one piston is pushed out, to replace the dirty screen by a fresh one, then put into the working position.the next step, the same job with the first piston, the screen changed one after the other, so it's a continuous one, no interrupted the production when change the screen.

And we do some change to make the screen changer become more effective. Sometimes we do not use the round breaker plate , but oblong ones, we adopt this way to increase the screen area to meet up the high yield device. Even some time we increase the screen area like this: the two pistons, we change them to the slide bar with holes, then wrap the screen around the slide bar with hole.

And get the much larger screen area to meet the requirement of the customers.

THe following are some pictures of the plastic extruder screen changer applied for the platic extrusion machine .

THe following are some pictures of the plastic extruder screen changer applied for the platic extrusion machine .