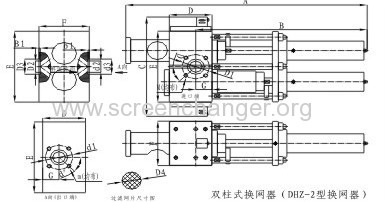

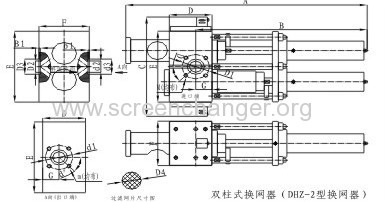

Double piston continuous screen changer for plastic extrusion machine

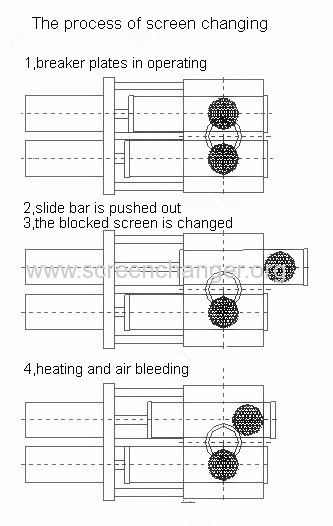

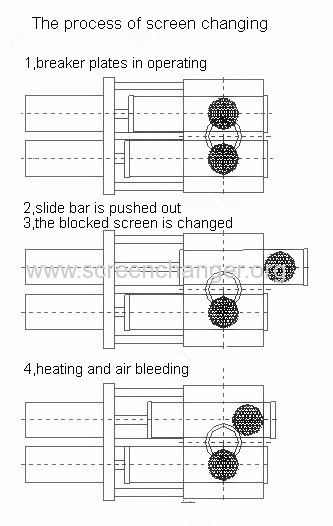

There are two filter screens in this kind of screen changer, in the normal time, the two filter screen are both on the working position, and when screen change required, one screen is pushed out and then replace the dirty screen, the other is still on the working position. and the following step will repeat the first step, so in the whole precess of the screen changing, there is no need to stop the on-going machine, and the production is always continuous, no amy interrupt.

| Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | Φ300 | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | Φ900 | 900x2 | 14 | 2000--6000 |

The following picture shows the process of the screen changing

Applications

cast film (Bubble pack\ Medical\Food Wrap)

Sheet (Foam\Strapping\Plastic cardboard)

Coating (Hot melt adhesive)

Pipe (Corrugated\Gas Pipe) and profile

Compounding (Master Batch\filler)

Wire and cable extrusion

Tubing (Medical\ Industrial\Irrigation)

Fibers (Monofilament)

Blow molding

Pelletizing (strands and underwater)

Recycling of most polymers

Some pictures of the double piston continuous

screen changer for plastic extrusion machine