Widely used plastic extrusion machine screen exchange filter

| Price: |

1.0~40000.0 USD |

| Payment Terms: |

T/T |

| Place of Origin: |

Henan, China (Mainland) |

Product Detail

Model No.:

DHZ

Production Capacity:

100 sets per month

Delivery Date:

40 days after receiving dow...

Function:

polymer melt filtration

Product name:

screen changer/ melt filter

Application:

almost all polymers PP/PE//...

Pressure resistant:

350bar

Means of Transport:

Ocean,Land,Air

Packing:

seaworthy packing

Structure:

Hydraulic Filter

Brand Name:

DEAO

Attribute:

auxiliary equipment of plas...

Material:

high quality alloy steel /3...

Type:

different types to be match...

1,Widely used plastic extrusion machine screen exchange filter

2, No disturb the production when change the screen

Widely used plastic extrusion machine screen exchange filter

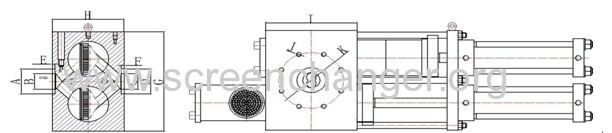

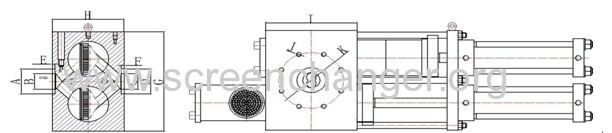

continuous screen chager, double piston screen changer, hydraulic screen changer

Features included

1,Double-piston screen changer works simultaneously. One net works. Another replaced; without interrupting the flow of material and production. And eventually fulfills the exchange of screen without stopping the machine.

2,Exhaust system device can fully defuse the gas mixed in the materials, then improving product quality. And double channels expand the filtration area to meet more productive, more high-quality production need s from customers.

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | square screen | 900x2 | 14 | 2000--6000 |

Technical Specifications

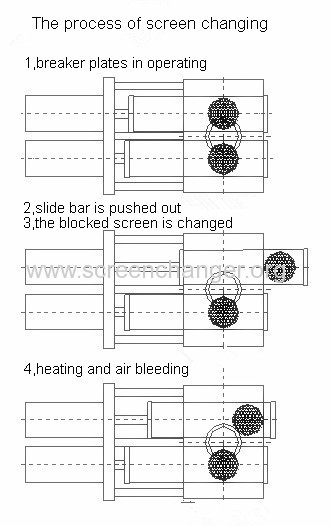

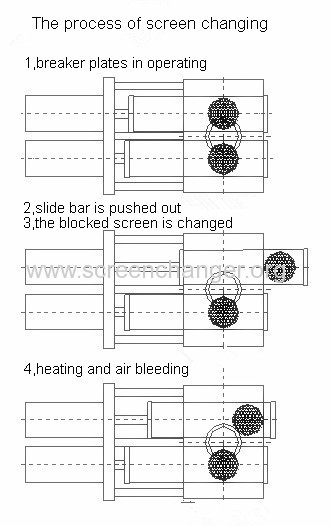

How to work

The double piston Screen Changer allows for filtration of most all polymers without interrupting production during a screen change. The

Screen Changer consists of two pistons with each containing a filter cavity. When a screen change is required, one of the pistons is moved out of the housing while the other remains in the operating position. The dirty screen pack is removed and replaced with a new one. The piston is then moved back into the housing to its venting stages before resuming operation. These steps are then repeated for the other piston. This concept allows for continuous filtration with no interruption or loss of production

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com