|

Deao Science & Technology Co., Ltd.

|

| Price: | 1.0~40000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Continuous screen changer -double piston screen changer

Double-piston continuous screen changer realizes a non-stopping screen changing operation by altering two pistons with double filtering areas. During production, the polymer melt is divided into two flow channels inside the screen changer housing, then conveyed through the two filters equipped with the appropriate filter medium. This filter medium consists of screen packs supported by breaker plates.

Features of continuous screen changer-double piston screen changer

1. Special sealed structure design(self-owned patent),excellent effect, no material leakage for more than five years.

2. Dual channels for filtration, no need to stop the working machine when changing the screen, no production interrupt, and more efficiency and less energy consumption without any defective product. Especially appropriate for the production of cast film, plate and sheet.

3. Simple construction, reliable operation; Easy maintenance, lower running cost;

Automatic screen changing by hydraulic; Machine non-stopped

4. The function of filling material exhaust and pollution discharge guarantee the process of replacing screen continuously. Exhaust system device can fully defuse the gas mixed in the materials and improve the product quality.

How to work of this kind of continuous screen changer

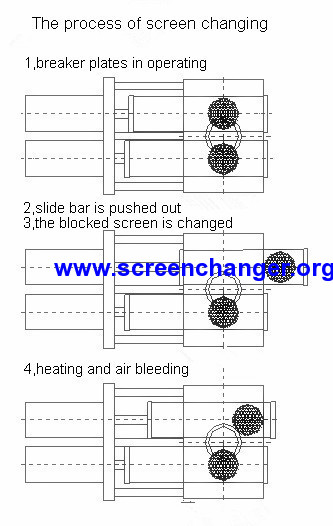

The double piston Screen Changer allows for filtration of most all polymers without interrupting production during a screen change. The Screen Changer consists of two pistons with each containing a filter cavity. When a screen change is required, one of the pistons is moved out of the housing while the other remains in the operating position. The dirty screen pack is removed and replaced with a new one. The piston is then moved back into the housing to its venting stages before resuming operation. These steps are then repeated for the other piston. This concept allows for continuous filtration with no interruption or loss of production

Applications

.sheet

.coating

.pipe

.compounding

.wire and cable

.tubing

.textiles(fibers and nonwovens)

.EVA, hot melt adhesive and PSA

.pelletizing(strands and underwater)

.recycling of most polymers

.blown film and cast film

.corrosive and degradable materials

.Textiles (fibers and nonwovens)

Technical Data

Type | Screen—Dm(mm) | Screen area(cm2) | Heating Power(kw) | Output(kg/h) |

DHZ-2-100 | Φ70 | 38 x 2 | 2 | 50--150 |

DHZ-2-120 | Φ90 | 64 x 2 | 4.6 | 100--350 |

DHZ-2-160 | Φ135 | 143 x 2 | 14 | 300--700 |

DHZ-2-200 | Φ155 | 187 x 2 | 14 | 400--1000 |

DHZ-2-300 | oval screen | 300x2 | 14 | 1000--4000 |

DHZ-2-1800 | square screen | 900x2 | 14 | 2000--6000 |

The continuous screen changer before deliver

The continuous screen changer applied in the actual production line